In recent years, manufacturing sites in the manufacturing industry have been changing dramatically, and one of the reasons for this is the rapid change in market needs in various industries. Because it is necessary to respond quickly to this, agility is also required in the manufacturing field.

For example, following price competition in the barren market and gaining market advantage through rapid deployment of new products and services are some of the factors. On another side, there is also anxiety about the acquisition of a certain number of excellent human resources equivalent to the present population in the direction of decline year by year. In such a modern market, activities such as the promotion of automation and labor-saving operations are being activated in the manufacturing field. In particular, in recent years, further evolution of its activities has begun with functions such as analysis using digital technology. While verifying such automation and digitization, ironically, there are many cases where problems in the current manufacturing field become apparent. Here, one of the common problems, “software operation by personal computer” in the manufacturing field, is explained based on a specific case. And we will also introduce how to solve it.

Problems at manufacturing sites – for software luck

Most modern factories have various systems to support manufacturing, and computers for handling this system are used in every scene in the field. This computer is placed in the vicinity of the work site because it is most often a terminal that controls a system closely related to the flow of manufacturing. In many cases, desktop and notebook PCs, so-called PCs, are used, and if you look around the entire factory, many PCs are deployed to support daily manufacturing operations.

However, there are actually challenges in the use of PCs in this field. Examples include updating software versions and introducing security patches. I think that even office workers are facing this problem about once every few years, but you will feel that updating your PC is more time-consuming and inconvenient than you think. You may say that if you re-download the necessary applications from setup or do poorly, you will not be able to work all day. What happens if this happens at the factory site? Even if you plan to update in advance, you have to stop a part of the equipment and line just for that, so it can be said that it is a very large and useless loss. Moreover, depending on the factory scale, there are thousands and tens of thousands of PCs, so it can be said that the renewal plan alone is considerable labor and effort. In such a situation, if there is software built on the basis of the older OS version, there will be a need for even greater effort. This is because additional measures and work such as the end of support such as OS security patches and maintenance frequency and spare parts due to aging of personal computers themselves occur. This can still be controlled as much as it is done in the updated plan, but one day when an event such as “Pc does not work” or “Software does not stand up” suddenly occurs, it is already a problem. In addition, since many manufacturing sites have repeatedly expanded and renovated equipment, software, and PCs of different versions and generations are mixed. It’s not an ordinary task to figure out, manage, and plan for response to all of which PCs have which generation of OS and which version of the software is running on it.

Of course, there are many commercial technologies to reduce such labor and effort. There is also a technology that makes it so-called compatible that absorbs the difference in version, and it is also possible to start the OS by a virtual environment method. However, such technology is only a countermeasure for the situation described above, and it cannot be said that it is a permanent measure. This is because as long as the system is operated on a pc located in the field, a dramatic reduction of maintenance man-hours cannot be expected.

Solution – Thin Client Solutions for Industrial Use

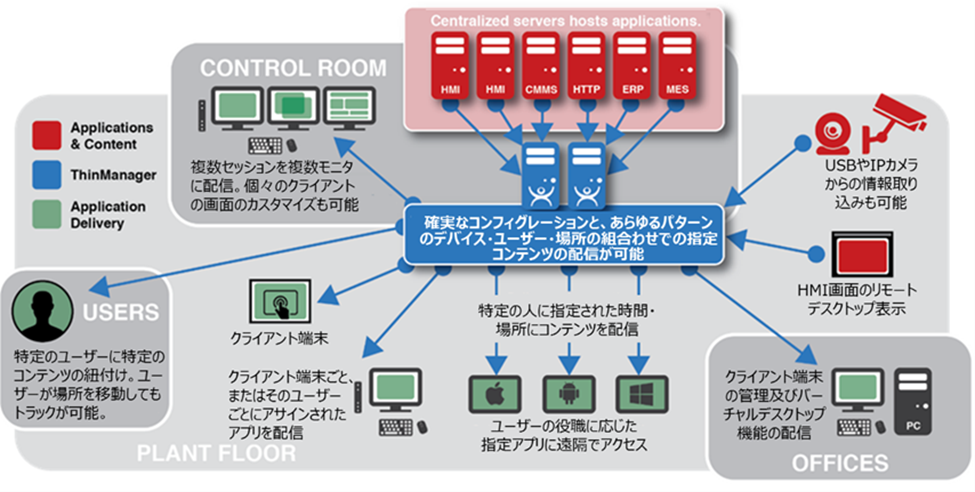

Therefore, a fundamental solution method is focused on a method using thin client technology that solves by consolidating disjointed PCs into a single platform. A thin client is a general system architecture in which the user’s client terminals do the least necessary processing and most of the processing is concentrated on the server-side. As a result, the client-side terminal receives a server-side operation screen, a screen such as a data dashboard (referred to here as content), performs only limited processing, and leaves most processing to the server-side, such as running applications and managing data. The mechanism itself is not new and is provided by several companies, but Rockwell automation’s software solution called “ThinManager” is provided by Rockwell automation on the client-side. It’s also very easy to add and update clients because you can manage everything in the center without having to. In addition, ThinManager covers the functions of general thin clients and supports equipment used uniquely to manufacturing sites such as industrial touch panels and IP cameras. Features such as extended screens are also supported. ThinManager is the only company that can provide thin client solutions for both office and manufacturing field applications.

“ThinManager” provided by Rockwell Automation

In recent years, thin client solutions have been rapidly used in industrial applications because many client terminals can be deployed and centrally managed at multiple sites, and it is possible to operate easily even in environments where there is no IT-saving personnel in the field. ThinManager, a centralized management solution that seamlessly integrates industrial computers and thin clients, enables sustainable, scalable platforms to reduce management and maintenance costs and increase security, regardless of the size of the industrial environment or the number of facilities.

Learn more about Rockwell ThinManager