In the previous article (Common issues in manufacturing sites – maintenance work of PCs and software), I explained the use of many PCs in manufacturing sites and their risks, and introduced solutions for those risks. Here, we will introduce the actual use of the solution in what and for what reason based on the case.

Case 1 – Thousands of PCs scattered across car companies

First of all, I would like to introduce a case study of ThinManager solution of an automobile company. One automaker was struggling to handle the thousands of PCs used in factory sites. The OS version was also different, and even though chocolate stops frequently occurred due to the pc stopping, there was naturally no budget to update thousands of PCs all at once. So let’s start by thinking about some scenarios. I erased the simultaneous update of the PC for the reason that it was almost impossible to perform the setup work all at once, but the number of chocolate stops in the last few months and the time it took to respond were converted into money by saying that it was a loss of opportunity to stop the line. Next, we calculated the introduction of thousands of new terminals (tablets that are not PCs) + thinManager license costs and new server installation costs, and compared them with the previous opportunity loss cost. This alone raised the military to the ThinManager introduction plan, and adoption was decided. The process from pc to client terminal was also a few years of work, but now it is all turned into a client terminal and running without problems.

Case 2 – Offshore Plunges of Oil Refining Companies

The following is an example of an oil refining company. As a matter of fact, it is the same as the case of the above-mentioned automobile company because it is a problem of personal computers scattered in the plant, but this company with an offshore plant cannot call support for the recovery of PC trouble. Therefore, it can be fatal if it takes time to recover. In addition, since the core systems that connect the entire company were also aging, updating this place would require a huge amount of time to re-put applications on many PCs. This is also a big risk for offshore work, so ThinManager was evaluated in terms of avoiding such risks, and it was introduced.

Case 3 – Robust mechanism that does not stop the production line

So far, we have introduced user examples that centrally manage PCs that were disjointed by adopting ThinManager on a sustainable and highly scalable platform to achieve high ROI effects and risk hedging. We will introduce cases that ensure high reliability that goes one step further.

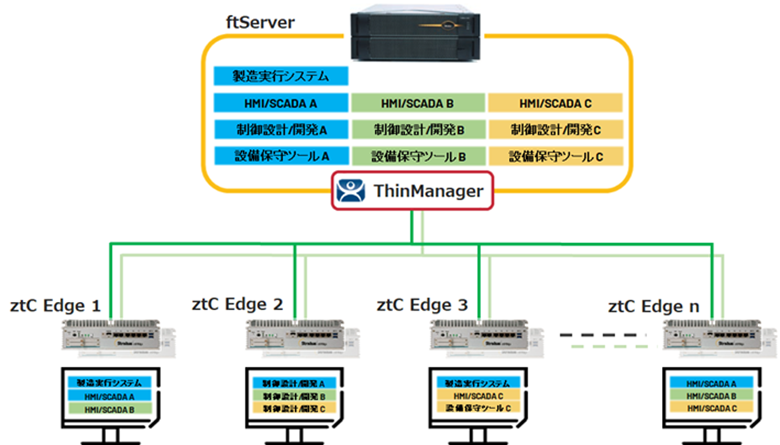

The system in the manufacturing industry cannot be stopped once it has started to move. With a thin client solution, most of the processing is centrally managed on the server side, so the impact of a server failure is enormous. However, in the event of a server failure, there are rarely sites where you can have the right people to respond quickly. Therefore, platforms that run thin client management software must be highly available to avoid the risk of a manufacturing business stopping.

That’s why we’ll show you a robust, highly available industrial computer that keeps it running without disruption (=ztC Edge) on the OS, thinmanager on ztC edge, a combination solution that provides a mechanism that allows you to manage and operate your applications in bulk.

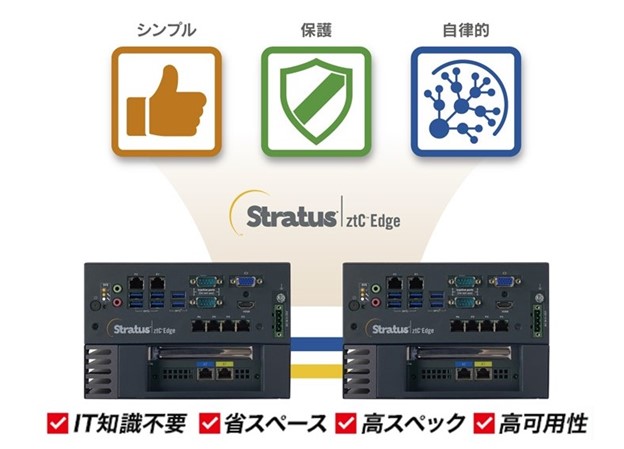

Stratus ztC Edge, a simple, robust, and highly available industrial computer

The terminals that receive the contents managed by ThinManager support not only PCs but also mobile terminals such as tablets and smartphones. In addition, since the OS and applications are centrally managed as distribution sources, tasks such as software updates and security patching can be centrally handled on the source side, providing significant improvements to conventional maintenance tasks. In combination with the highly reliable ztC Edge as a “server that does not stop”, there is no worry of shutdown on the center side, and since it is a content delivery format, the receiving terminal becomes a pure operation-only terminal, and in the event of a terminal nonconformance, it can return to work and business by simply replacing it with a new terminal. This saves you the trouble of re-downloading and reconfiguring the OS and apps even if the terminal in the field suddenly stops working or breaks down.

The company responsible for LPG refining and pipeline supply in the U.S. was among the first to implement this combination solution, where more than 6,000 miles of pipelines and 100 more than one track terminal. A considerable number of PCs were used at purification plants, truck terminals, and pipeline maintenance sites, but in addition to the opportunities and losses as described above, we were also very concerned about security. Oddly enough, cyberattacks on gas pipelines in the U.S. have recently become a hot topic, but by preventing them, robustness to networks and center/edge servers has become a major solution choice. Therefore, thinManager application software, ftServer for center server, ztC Edge for edge, and now the adoption is progressing smoothly.

So how did you do that? These are just a few examples. I think that the accumulated work experience of each company is reflected in the system operated today. If there is new work experience tomorrow, it will be revised /reflected in tomorrow’s system. And as manufacturing becomes IoT in the future, the need for thin clientization + security response is expected to continue to increase in the future. ThinManager on ztC Edge supports customers in order to reduce operation after the introduction of the system in the field of manufacturing that changes every day.